Processing Technology

Consistent high-level stainless steel processing technology inherited from Japanese companies

Inheriting stainless steel processing technology which was developed by Nissho Astec Co., Ltd. in Japan and having various processing processes such as machining, buffing, electrolytic polishing, welding.

Vina Astec is capable of handling mass production products, custom-made products, and construction projects.

In recent years, we have been receiving high evaluation not only from Vietnamese and Japanese companies, but also from various companies in neighboring countries.

Machining

We have several medium-sized NC machines and general-purpose cutting machines.

With these cutting machines, we can handle casting dies, press dies, screw joints, small parts, etc., from 1 piece to annual mass production.

In prefabricated piping, after being cut accurately, following by the chamfering cutting process, finished products always has a stable weld finish.

Also, since it is the key to manufacturing equipment and jigs for other processes, one of our strengths is our machining team.

Welding

Our welding team is operated by welding workers who have spent more than 3 years in Japan to work as technical trainees and they have acquired the JWES professional grade qualification.

Thanks to this, we can offer high-quality TIG welding that satisfies customers regardless of whether it is automatic welding or manual welding.

We also perform airtight inspection and water pressure inspection after welding.

Cold Pressing

We shape and bend thin steel sheets with a cold press machine, and provide products that meet the strict standards of overseas companies, mainly in Japan.

In addition, by cooperating with the machining team, we are able to smoothly handle from mold production to trial production to mass production.

Currently, about 3,000 pressed products and the same amount of pipe hangers are exported to Japan every month.

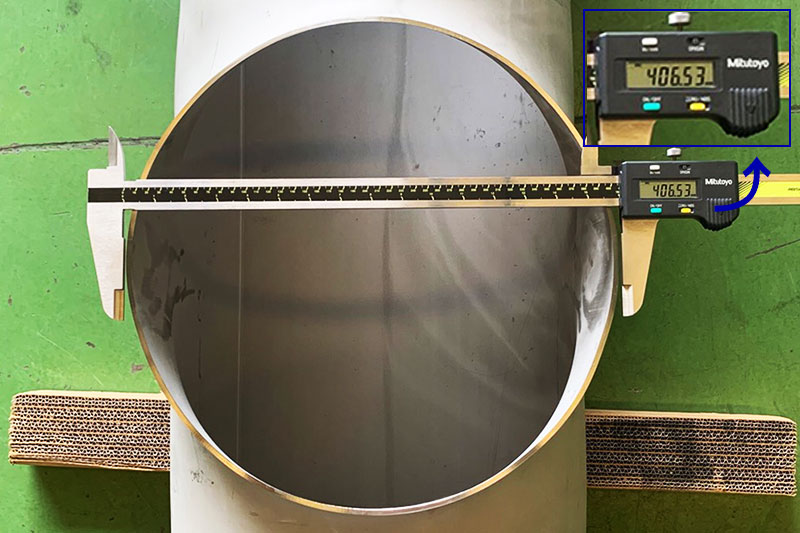

Burring

One of our strengths is the burring process.

We have completely inherited the burring technology, which is the strength of our parent company, Nissho Astec, and now, we are proud to be able to provide the same quality as in Japan.

We can perform burring process on big size pipes like 400A pipe with same burring diameter. The burring process makes it possible to manufacture branch pipes without using TEE fittings, reducing the number of welding points and improves the accuracy of the pipe length, which shortens the pipe assembly time on site and leads to a reduction in total cost.

The types of burring dies are increasing gradually, so please feel free to contact us for available sizes.

Buff Polishing (for Fittings and Parts)

One of our strengths is our buffing team. Most of our more-than-80-worker team have reached the craftsman level.

In addition, the strength of buffing is not limited to the quality and quantity of craftsmen. We are particular about the polishing materials used, and we manufacture flap foil and tripoli in-house.

We use carefully selected auxiliary materials, including purchased items. Therefore, our polishing quality always maintains high stability.

* Please contact us for consultation about mirror finish buffing of titanium products.

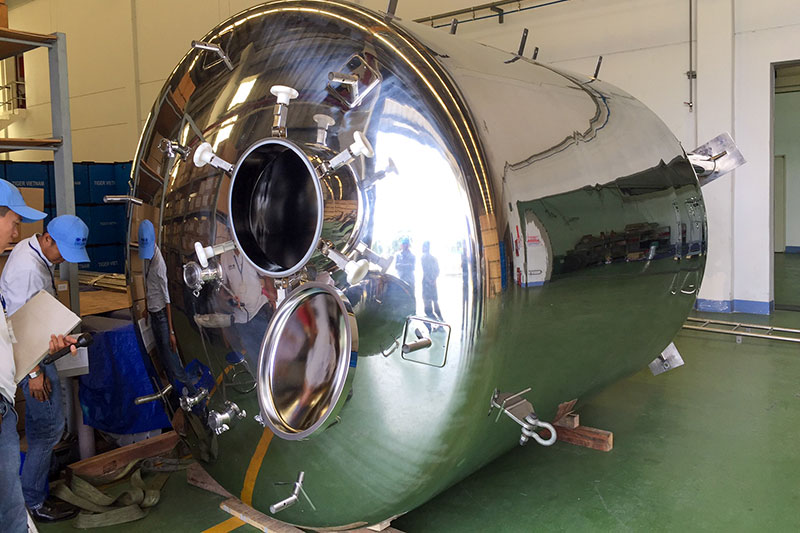

Buff Polishing (for Tanks and Containers)

Having multi-skilled polishing craftsmen who are few in number in Southeast Asia, we were able to form up a team to provide polishing services for large products, including containers.

We also repair tanks that were polished by other companies; and provide on-site polishing services.

Buff Polishing (for Pipes)

One of our advantages is that we can make the necessary equipment in-house. We manufactured all of our pipe inner surface polishing machines and pipe outer surface polishing machines in-house.

In addition, we have two types of equipment for inner polishing, the “vertical polishing method” and the “horizontal polishing method”, and the equipment is properly used in accordance with pipe’s inner diameter.

The maximum length of a pipe that can be polished is 6 meters, and up-to-20-meter pipe can be polished when performing internal vertical polishing.

Since polishing takes a large amount of time depending on the skin condition before processing surface, the quotation may be just approximate estimate if there was no sample pipe in advance.

Buff Polishing (for Plates)

One of our strengths is that we can make the necessary equipment and jigs in-house, and we also manufacture automatic steel plate polishing machines. This polisher is intended for polishing the base of steel plates for tank manufacturing, so it is not suitable for products require finer finish like decorative steel plates.

By automating this base-level-polishing, we are contributing to cost reduction and quality improvement of large container manufacturing.

Maximum size of steel plate ever polished at our factory: plate thickness 25mm, width 1.214meters, length 10.0meters, weight 2,422kg/sheet.

Vibration Polishing

Vibration polishing is a finishing method that gives a spiral pattern or random polishing pattern to the stainless steel products’ surface, and is used for finishing cast products and deburring mass-produced parts.

Although vibration polishing does not have the cutting force of manual buffing, products undergoing this process can be deburred evenly, and you can expect a uniform, high-quality finish.

We accept requests for vibration polishing only.

Surface Polishing

Surface polishing requires that the objects to be flat to polish. However, highly precise polishing can be achieved.

Currently, we are taking orders for polishing parts of facial massagers (parts that directly touch the face) and blades.

Please feel free to contact us, although the objects are limited to small size only.

Electro Polishing (for Fittings and Parts)

One of our strengths is electro polishing/EP.

Thanks to our strength of being able to make the necessary equipment and jigs in-house, together with the technology and know-how inherited from our parent company – Nissho Astec, we have been receiving orders from not only companies in Vietnam but also in Japan, East Asia, Southeast Asia, and Europe.

We may undertake on-site EPs depending on the circumstances, but as a general rule, operation is done within our factory. Electropolishing of materials other than austenitic stainless steel often requires time for testing and verification.

About electro polishing (EP) ; NISSHO ASTEC CO., LTD.

About electro polishing (EP) of aluminum

*EP:Electro Polishing

An electrochemical process that reduces the surface roughness of metals such as stainless steel, aluminum, and titanium by an electrolytic reaction to form a passivation film with concentrated chromium. After the process, the surface finish of the metal becomes strong, smooth and shiny.

Electro Polishing – EP (for Pipes)

Plan to start mass production EP from 2024

Currently, our parent company Nissho Astec (Japan) will undertake electropolishing of pipes with length of more than 2 meters, but if it is determined that the specifications are unsuitable for the parent company’s preference, we will take over the work.

Length of the longest pipes underwent inner EP process at our factory: 12 meters (OD25.4φ x thickness1.2mm)

Electro Polishing (for Tanks and Containers)

One of our strengths is large tank EP/small container EP.

Since we started electro polishing of containers for the first time in Vietnam, we have grown to be recognized as a leading EP service provider in Vietnam.

We make specialized equipment, jigs and tools in-house according to the final purpose, and provide electro polishing/EP to meet your needs. Some of these equipment and jigs are unique in the world.

The maximum stainless steel container’s capacity in the past: 15,000L

EP quantity of small containers processed annually for mass production: 1 million bottles a year

Degreasing Cleaning

Cutting oil, metal powder, buff powder, etc. are often found on the surface of processed stainless steel, and unpackaged stainless steel products that have been stored for a long period of time always have dust or oil due to the warehouse and factory atmosphere.

We call the process which removing dirt and dust with an alkaline cleaner as “Degreasing cleaning”. This is one of the treatment methods used as oil-free treatment.

As for water used for rinsing after degreasing, we use stored pure water.

We also accept requests for embargo processing and degreasing cleaning only.

Acid Cleaning

We operate the dipping method using a pickling solution with the base consisting nitric acid and hydrofluoric acid.

If the product has a gap that causes liquid pooling, we suggest clients to fill it with welding spot if possible.

We support requests for only pickling.

Pure Water Cleaning

Pure water, which contains almost no impurities, can clearly show the properties of water, and has an even stronger ability to dissolve things. Taking advantage of these characteristics, ultrapure water is used in the rinse process after EP treatment.

Assembly/Production

By unitizing valves and equipment, we realized many advantages such as improved operability and maintenance during equipment operation. Unitized unit also has excellent workability and enables smooth installation and adjustment within a tight schedule for plant construction.

Since we are good at in-house processing, we manufacture units that have high dimensional accuracy of each piece and can easily attach and detach pipes. Moreover, we are also capable of gathering parts materials and making in-house parts, we can handle a wide range of items from small cases to piping system.

Inspecting

The quality and quantity of the inspection staff are sufficient to perform checks that are essential to product quality, such as tests for product dimensions and appearance, and molybdenum checks.

Quality management

Our company has obtained the certification of the quality management system “ISO 9001:2015” stipulated by the International Organization for Standardization (ISO) from Intertek Cetification Limited.

ISO 9001 is a standard that defines a wide range of quality management requirements, from product and service quality assurance to organizational management including customer satisfaction and improvement.

On-site Plumbing

One of the strengths of our partner company, Matsusho Koki Co., Ltd. (with Matsusho Vietnam as the local subsidiary), is on-site plumbing work, and the members who received training from the company are mainly at the site to carry out on-site plumbing work.

We support on-site processing, installation, and inspection such as process piping, utility piping, and handling support materials. In particular, we have received high recognition in fields that require high quality levels, such as pharmaceuticals, semiconductors, beverages, and foods.

On-site Polishing

If the object to be polished cannot be removed from the site, or if it cannot be removed from other equipment, our staff will visit the customer’s site to confirm the work place and necessary equipment materials, then carry out the polishing work.

If you need curing work the day before the work or cleaning work the day after the work, please let us know.

In the case of distant place, travel expenses and transportation expenses for site confirmation work may be charged separately.